FOCUSTECH™ Process Control Systems

About Process Control Systems

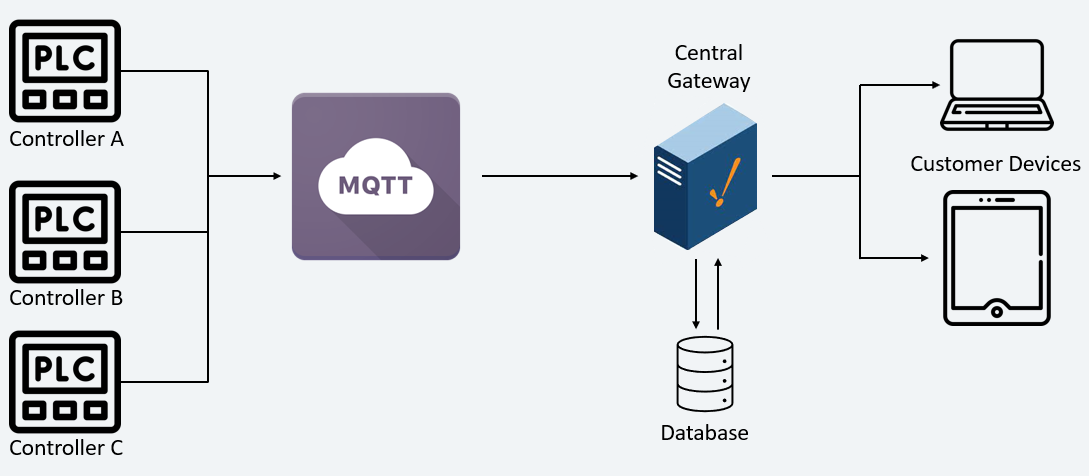

All FOCUSTECH™ Process Control Systems are connected factory capable, allowing users to track process status, alarm conditions, and data logs from anywhere in the world with an internet connection.

Click here to learn more about our Connected Factory Platform.

Don’t see a controller here for your process? Contact us, and we will custom-design a system that meets your needs.

Connected Factory - How It Works

Process Control Systems

The CONDUCTROL CC-1000 provides accurate, reliable control for all cleaning processes. The CONDUCTROL CC-1000 controls solution concentration based on conductivity and process level with freshwater additions.

Features:

- Chemical make-up based on conductivity

- Multiple chemical delivery options

Benefits:

- Very accurate concentration control and adaptable to many different processes

- Compatible with any size process or feed requirement

The AUTOdose PC-1001 provides accurate, reliable control for most conveyorized

processes using panel count technology to initiate replenishment. It controls solution

concentration, chemistry replenishment, and bath loading.

Features:

- Automatic delivery of replenishment chemicals from factory packaging or from working solution directly to the process

- Compact, wall mount design

Benefits:

- Minimizes chemical handling

The µETCH EC-2000 provides accurate, reliable control for all copper microetching processes.

Features:

- Colorimetric copper control

- In-tank or flow-through sensor options

- Optional degasser

Benefits:

- Accurate, reliable process control

- Optimize performance based on immersion or conveyorized application

- Improves control of peroxide/sulfuric microetches

The IMAGEpro DC-3020 provides accurate, reliable control for developing processes.

The DC-3020 controls solution concentration, resist loading and, most importantly,

process breakpoint.

Features:

- Volumetric working solution preparation

- Automatic make-up and delivery of replenishment chemicals from factory packaging to the process

- Multi-channel option

Benefits:

- Very consistent concentration control

- Minimizes chemical handling

The IMAGEpro DC-3030 provides accurate, reliable control for developing processes. The DC-3030 controls solution concentration, resist loading and, most importantly, process breakpoint. Automatic delivery of chemical concentrate directly from factory packaging minimizes chemical handling.

Features:

- Dosing pump, on-demand make-up and replenishment

- Compact, wall mount design

- High quality process instrumentation

Benefits:

- Simple and cost effective

- Saves space and is easy to install

- Accurate, reliable process control

The IMAGEpro DC-3070 provides accurate, reliable working solution for developing

processes. The IMAGEpro DC-3070 controls solution concentration and works in

conjunction with process controls at each individual process to control resist loading

and, most importantly, process breakpoint.

Features:

- Conductivity based chemical make-up

- Multi-channel option

Benefits:

- The most accurate concentration control of all system designs

- Control up to three processes with one controller

The ETCHpro CC-4000 provides accurate and reliable control of your cupric chloride etching

process through independent measurement and adjustment of the three critical control

variables: cupric chloride concentration, free acid and total metal loading.

Features:

- Tri-Sensor System (ORP, Conductivity and Specific Gravity)

- Toroidal (non-contact) conductivity measurement

- Multi-junction ORP electrode design

Benefits:

- Optimize each control variable for specific performance requirements

- Superior sensor performance and durability provides accurate, reliable control of free acid

- Unparalleled accuracy and sensor life

The ETCHpro FC-4020 provides accurate and reliable control of your ferric chloride etching

process through independent measurement and adjustment of the three critical control

variables: ferric chloride concentration, free acid, and total metal loading.

Features:

- Tri-Sensor System (ORP, Conductivity and Specific Gravity)

- Toroidal (non-contact) conductivity measurement

- Multi-junction ORP electrode design

Benefits:

- Optimize each control variable for specific performance requirements

- Superior sensor performance and durability provides accurate, reliable control of free acid

- Unparalleled accuracy and sensor life

The AUTOstrip RC-5030 provides accurate, reliable control for stripping processes.

The RC-5030 controls solution concentration, resist loading and, most importantly,

process breakpoint.

Features:

- Dosing pump, on-demand make-up and replenishment

- Compact, wall mount design

Benefits:

- Simple and cost effective

- Saves space and is easy to install

The AUTOstrip PC-5040 provides accurate, reliable control for resist stripping processes. The AUTOstrip PC-5040 controls solution concentration, resist loading and, most importantly, process breakpoint. Automatic delivery of chemical concentrate directly from factory packaging minimizes chemical handling.

Features:

- Panel count based replenishment

- Dosing pump, on-demand make-up and replenishment

Benefits:

- Simple and effective with no pH probes to calibrate

- Consistent and cost effective

The FILTERpro RS-5050 separation unit is a high-capacity continuous process filter that quickly and efficiently removes dry film particles from stripping solutions.

Features:

- Filters 100% of the working solution

- Heavy-duty materials of construction

- Flow rates up to 160 gpm

- Variable speed control of drum rotation standard on all units

Benefits:

- Improved resist removal reduces cost

- Years of reliable service

- One unit can filter multiple strip modules

- Optimize performance without having to pay more

The Gravitrol SG-7000 provides accurate, reliable control for nitric acid-based tin and solder stripper processes. The Gravitrol SG-7000 continuously monitors process-specific gravity and automatically adds fresh stripper solution when the specific gravity climbs above the user-defined set point.

Features:

- High quality process instrumentation

- Automatic delivery of replenishment chemicals from factory packaging or from working solution directly to the process

- Compact, wall mount design

Benefits:

- Accurate, reliable process control

- Minimizes chemical handling

- Saves space and is easy to install

The EN-8000 Electroless Nickel Controller uses a field-proven sample cool measurement technique that eliminates problems associated with measuring pH at elevated temperatures.

Features:

- Colorimetric nickel control

- pH is measured using a proprietary pre-amp

Benefits:

- Most consistent concentration control

- Eliminates problems with ground faults commonly associated with electroless baths